This New Tech Shakes Up LED Lighting in California

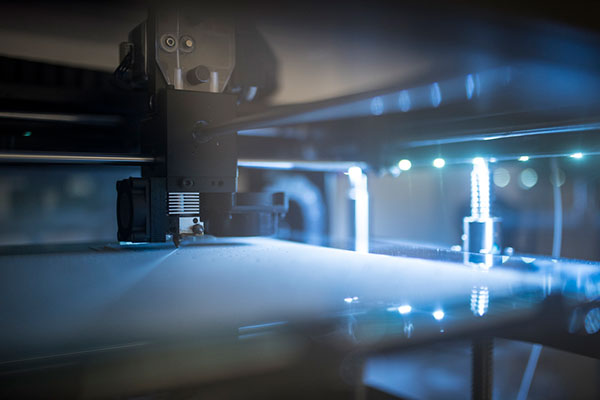

Unequaled by any other light source, LEDs are increasingly being used in various applications such as 3D printing. In 2014, 3D manufacturing techniques started to be utilized in LED lamp fabrication. Compelling ideas were formed on how 3D printing processes can take advantage of the the solid-state lighting (SSL) industry, though resources were quite costly. Over time, the bulky 3D equipment adapted smaller sizes and price ranges dropped to a more attainable level for educational and recreational uses. Stunning 3D printing creations put many in awe of technology. With LED added in the picture, we’re looking at even more enhanced outdoor lighting design offerings.

In a presentation created by Dr. Nadarajah Narendran, research director at the Rensselaer Polytechnic Institute Lighting Research Center (LRC) in Troy, NY, together with research scientist Dr. Indika Perera, created a presentation about their studies on 3D printing or ‘additive manufacturing’. The research involved the role of 3D printing techniques for SSL components and LED luminaire design customizations. The results might be the key to significant breakthroughs in terms of decreasing manufacturing costs, inventory components, and time-to-market.

Additive manufacturing pertains to the fabrication of a 3D object wherein a print head or nozzle is used to deposit a polymer-based material layer by layer according to digital information acquired from a computer-aided design (CAD) model. Fabrication methods have been successful on diverse markets including automotives, medical devices, and aerospace. The primary goal of merging SSL technology with additive manufacturing is to achieve design uniqueness.

Energy efficient, economical, durable and requiring less frequent replacements make LEDs the preferred lighting system of today. These benefits of LED lighting in Nevada, combined with customizable lighting fixtures unique to the design and requirements of the space that needs illumination are bound to yield great outcomes. Additive manufacturing for SSL will enable rapid prototyping and product introductions, custom fixtures and components, improved visual appeal, better functionality, and reduced fixture costs.

Lighting professionals can manufacture custom lighting fixtures onsite during building retrofit and construction projects. Real-time capability to produce a new fixture helps manufacturers free up stocking requirements, rather have them printed on demand. The combined technologies can also lead to mass customization of lower-cost lighting systems. It also supports sustainability without the need craft lighting fixtures in one location, only to ship in different parts of the globe.

Contact Great Basin Lighting for Outdoor, Roadway and Municipal LED Lighting

Additive manufacturing in the SSL industry holds a promising future. Challenges are yet to be overcome, especially with structural, electrical, thermomechanical components and optics required in LED system manufacturing. Formulating an integrated approach to fabricate a product with multiple parts and functionalities, along with the availability of suitable materials would likewise have to be considered. Custom-made, unique and attractive LED outdoor lighting by Great Basin Lighting are popping up at businesses and municipalities across California and Nevada.

For custom outdoor, roadway and municipality LED lighting, contact the team at Great Basin Lighting today! For more information call (925) 240‑1566 (CA), (775) 333‑0900 (NV), or contact us online.